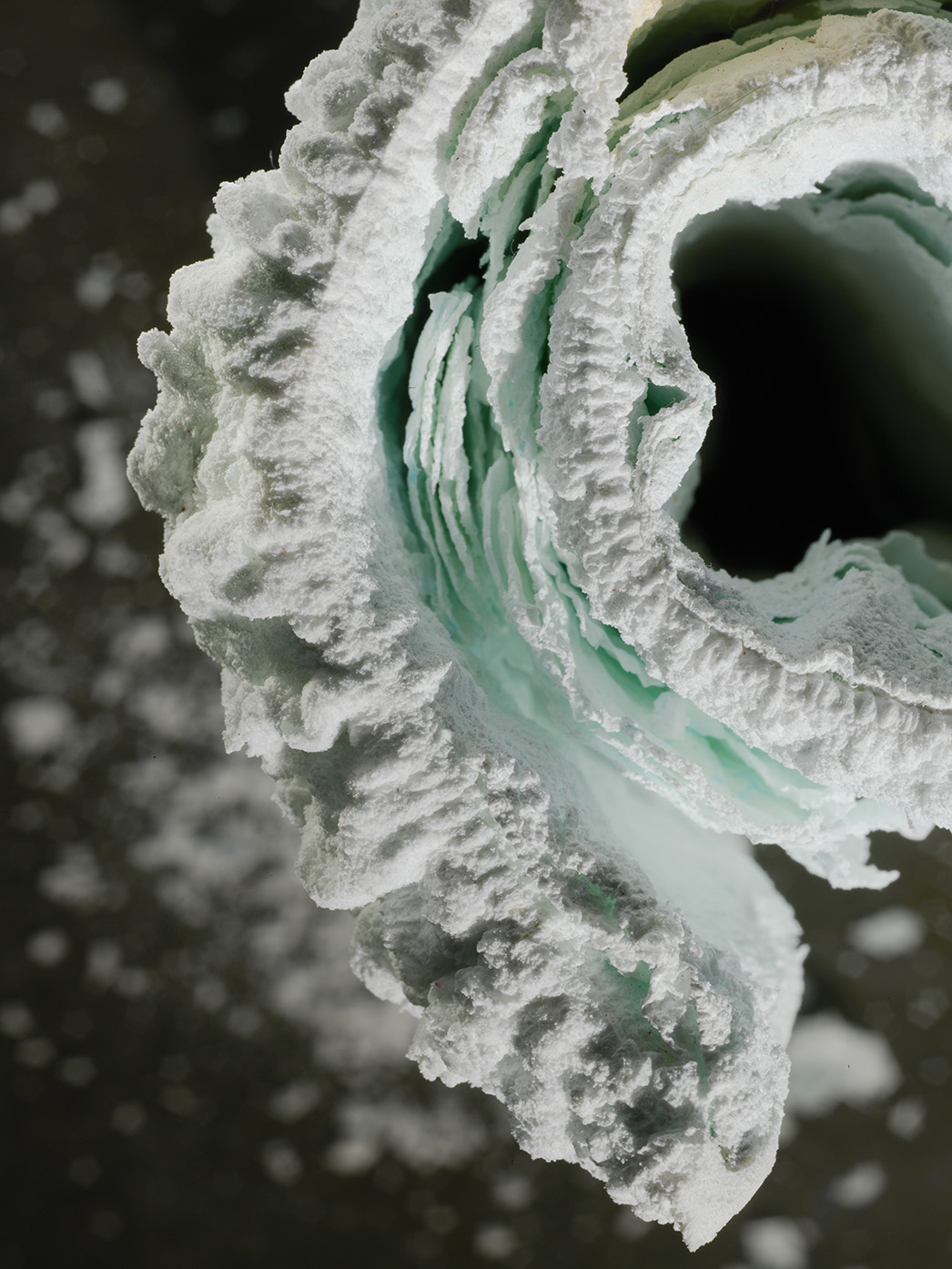

Lead White pigment

THIS IS THE GREATEST – AND THE CRUELLEST – OF THE WHITES.

Lead white has been in continuous production for at least 2000 years. It is basic lead carbonate, formed by the reaction of lead with vapours of vinegar (acetic acid) and carbon dioxide. The manufacturing process in the 19th century was relatively unchanged from that used in the classical world.

The introduction of the ‘stack’ method in the 16th century refined the procedure to improve the pigment’s quality. Specially constructed clay pots were divided into two separate chambers, one for the lead and the other for vinegar. Dozens of pots were lined up, covered then surrounded

with large quantities of warm manure that produced carbon dioxide as well as the heat needed to accelerate the reaction. Multiple layers of pots were stacked and covered with more manure. The room was sealed and left closed for up to 90 days. This alchemical magic is the result of the corrosion of the metal, which transforms grey lead into the purest white. The process turns the solid metal into flakes, which is why lead white is also known as flake white.

For hundreds of years, this dense silver-white has been the most important pigment for artists. It is hard to imagine the history of art without it. However, it has one major defect: lead is so poisonous that prolonged exposure will kill you. This is not such an issue for artists, whose contact with it in paint is limited, but for workers in lead white factories the symptoms of poisoning included headaches, memory loss, abdominal pain and eventually death.

In the late 19th century, safer synthetic whites superseded lead white. Zinc white was its first competitor and then, in the 20th century, the introduction of titanium white almost completely replaced lead white’s commercial use.